When designing electronic circuits, engineers frequently face the crucial decision between implementing an LC vs RC low-pass filter configuration. Both filter types serve the essential purpose of attenuating high-frequency signals while allowing lower frequencies to pass through, yet they operate on fundamentally different principles and offer distinct advantages for specific applications. Understanding the characteristics, performance metrics, and practical considerations of each filter type enables engineers to make informed decisions that optimize circuit performance while balancing cost, complexity, and design requirements.

The fundamental difference between these filter topologies lies in their reactive components and energy storage mechanisms. LC filters utilize inductors and capacitors, creating resonant circuits that can achieve sharp frequency cutoffs and minimal insertion loss in the passband. RC filters employ resistors and capacitors, offering simplicity and cost-effectiveness while providing gentler roll-off characteristics. This distinction influences every aspect of filter performance, from frequency response and impedance matching to physical size and manufacturing considerations.

Modern electronic systems demand increasingly sophisticated filtering solutions to manage electromagnetic interference, signal integrity, and power quality issues. The choice between LC and RC configurations often determines the success of applications ranging from audio equipment and telecommunications systems to power supplies and motor drives. Engineers must carefully evaluate factors such as insertion loss, roll-off rate, component tolerances, temperature stability, and electromagnetic compatibility when selecting the optimal filter topology for their specific requirements.

Fundamental Operating Principles

LC Filter Operation and Characteristics

LC low-pass filters operate through the interaction between inductive and capacitive reactances, creating frequency-dependent impedance characteristics that effectively separate desired and unwanted frequency components. The inductor presents increasing impedance to higher frequencies while maintaining low impedance at DC and low frequencies. Simultaneously, the capacitor provides a low-impedance path for high-frequency signals to ground while blocking DC components. This complementary behavior creates a natural frequency cutoff where the reactive components work together to achieve maximum attenuation.

The resonant frequency of an LC circuit occurs when inductive and capacitive reactances are equal, creating a point of minimum impedance that can be precisely controlled through component selection. Below the resonant frequency, the inductor dominates circuit behavior, while above this point, capacitive effects become predominant. This transition creates the characteristic frequency response that makes LC filters particularly effective for applications requiring sharp cutoff characteristics and minimal passband distortion.

Energy storage capabilities distinguish LC filters from their RC counterparts, as both inductors and capacitors can store and release energy without inherent dissipation. This property enables LC filters to maintain signal integrity while providing filtering action, making them ideal for applications where signal preservation is critical. The quality factor of LC components directly influences filter performance, with higher-quality components producing sharper frequency transitions and lower insertion losses.

RC Filter Fundamentals and Behavior

RC low-pass filters function through the time-constant relationship between resistance and capacitance, creating a gradual transition from passband to stopband frequencies. The resistor provides a fixed impedance that remains constant across all frequencies, while the capacitor's reactance decreases proportionally with increasing frequency. This combination produces a smooth, predictable roll-off characteristic that follows a first-order response curve with a -20dB per decade slope beyond the cutoff frequency.

The charging and discharging behavior of the capacitor through the resistor creates the fundamental timing mechanism that determines filter response. At low frequencies, the capacitor appears as an open circuit, allowing signals to pass through with minimal attenuation. As frequency increases, the capacitor's decreasing reactance provides an increasingly lower impedance path to ground, progressively attenuating higher frequency components. This gradual transition makes RC filters particularly suitable for applications requiring smooth frequency response without sharp discontinuities.

Unlike LC filters, RC configurations inherently dissipate energy through the resistive component, which can introduce insertion loss but also provides inherent stability and predictable behavior. The resistor's presence eliminates the potential for resonant peaks or oscillations that might occur in purely reactive circuits, making RC filters inherently stable and less sensitive to component variations or external influences.

Performance Comparison and Analysis

Frequency Response Characteristics

The frequency response differences between LC vs RC low-pass filter configurations represent one of the most significant factors in filter selection. LC filters can achieve much steeper roll-off rates, particularly in multi-section designs, with second-order LC sections providing -40dB per decade attenuation compared to the -20dB per decade characteristic of first-order RC filters. This enhanced selectivity allows LC filters to provide superior rejection of unwanted frequencies while maintaining excellent passband characteristics.

Insertion loss performance strongly favors LC filters in most applications, as the purely reactive components introduce minimal signal attenuation in the passband. High-quality LC filters can achieve insertion losses below 0.1dB, while RC filters inherently introduce loss equal to the voltage divider formed by the source impedance and filter resistance. This fundamental difference makes LC filters the preferred choice for applications where signal strength preservation is critical, such as RF communications and precision measurement systems.

Phase response characteristics also differ significantly between filter types, with LC filters potentially introducing phase shifts that vary nonlinearly with frequency, particularly near resonant points. RC filters provide more predictable phase behavior, with first-order sections introducing a maximum phase shift of 90 degrees. For applications sensitive to group delay or phase distortion, the choice between LC and RC configurations requires careful consideration of the acceptable phase response characteristics.

Impedance Matching Considerations

Impedance matching requirements often dictate filter topology selection, as LC and RC filters present vastly different impedance characteristics to source and load circuits. LC filters can be designed to provide specific impedance matching between source and load, with characteristic impedance determined by the square root of the L/C ratio. This capability makes LC filters particularly valuable in RF applications where precise impedance matching is essential for maximum power transfer and minimal reflections.

RC filters present simpler impedance relationships but require careful consideration of source and load impedances to achieve optimal performance. The filter's input impedance varies with frequency, starting at the DC resistance value and decreasing as the capacitive reactance becomes dominant at higher frequencies. Load impedance significantly affects RC filter performance, as light loading can alter the effective cutoff frequency and introduce additional roll-off beyond the designed response.

Driving capability represents another important distinction, as LC filters can handle higher current levels without significant power dissipation, while RC filters are limited by the power rating of the resistive components. This difference becomes particularly important in power applications where high currents must be filtered without excessive heat generation or component stress.

Design Considerations and Practical Applications

Component Selection and Tolerances

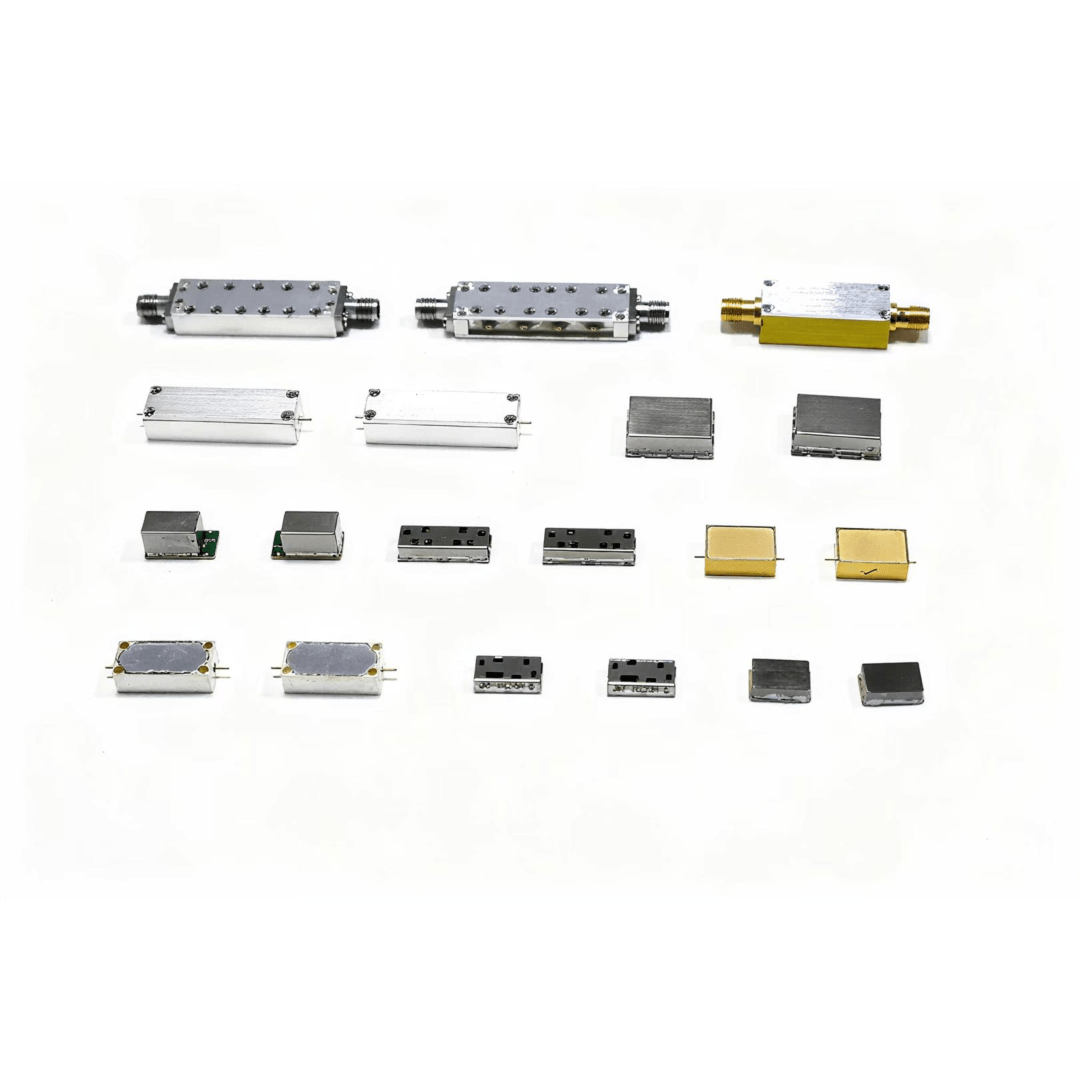

Component selection significantly impacts the performance and reliability of both LC and RC filter implementations, though the critical parameters differ between topologies. LC filters require careful selection of inductors with appropriate current ratings, DC resistance values, and core materials to minimize losses and prevent saturation. Capacitor selection must consider dielectric properties, temperature coefficients, and voltage ratings to ensure stable performance across operating conditions.

Tolerance accumulation affects LC and RC filters differently, with LC designs generally showing greater sensitivity to component variations due to the resonant nature of the circuits. A 5% tolerance in both L and C values can result in significant shifts in cutoff frequency and response shape, particularly in high-Q designs. RC filters typically demonstrate better tolerance to component variations, as the gradual roll-off characteristic is less sensitive to precise component values.

Temperature stability considerations favor RC filters in many applications, as precision resistors and capacitors can provide excellent temperature coefficients that result in stable filter performance across wide temperature ranges. LC filters face additional challenges from inductor temperature effects, including core material changes and thermal expansion of windings, which can alter inductance values and affect filter response.

Physical Implementation and Cost Factors

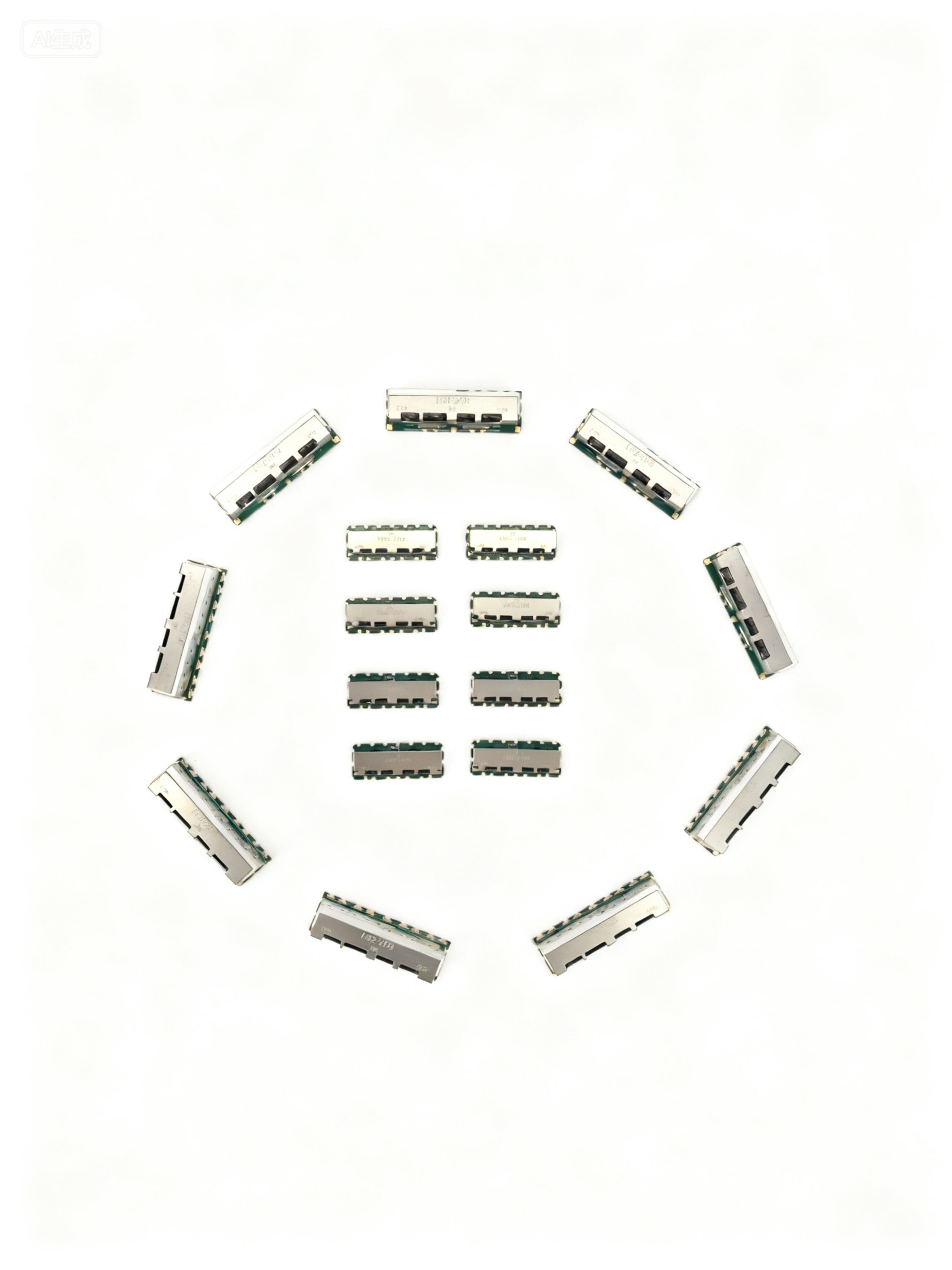

Physical size and weight considerations often influence filter selection, particularly in portable or space-constrained applications. RC filters generally require less board space and can be implemented using standard surface-mount components, making them attractive for high-density designs. LC filters, especially those requiring significant inductance values, may necessitate larger components or custom magnetic designs that increase overall system size and weight.

Manufacturing costs typically favor RC implementations due to the widespread availability and low cost of precision resistors and capacitors. Standard component values are readily available from multiple suppliers, enabling competitive pricing and reliable supply chains. LC filters may require custom inductors or specialized components that increase both initial costs and long-term procurement complexity, particularly for low-volume applications.

Assembly considerations also differ significantly, as RC filters can be fully automated using standard pick-and-place equipment, while LC filters may require manual handling of larger or non-standard components. This difference affects manufacturing throughput, quality control procedures, and overall production costs, particularly in high-volume manufacturing environments.

Application-Specific Performance Requirements

Audio and Communications Systems

Audio applications present unique requirements that often favor LC filter implementations due to their superior signal preservation characteristics and minimal distortion properties. High-fidelity audio systems demand filters that can remove unwanted frequencies without introducing audible artifacts or signal degradation. LC filters excel in these applications by providing sharp cutoffs that effectively separate audio bands while maintaining phase coherence and low insertion loss in the passband.

Communications systems requiring precise frequency separation benefit from the steep roll-off characteristics achievable with LC designs, particularly in multi-stage configurations. The ability to achieve 40dB or greater per decade attenuation enables effective channel separation and interference rejection in crowded frequency environments. However, RC filters find applications in communications systems where cost constraints or circuit simplicity outweigh the performance advantages of LC implementations.

Digital signal processing applications often utilize RC filters for anti-aliasing purposes, where the primary requirement is gradual high-frequency attenuation rather than sharp cutoff characteristics. The predictable phase response and stability of RC filters make them suitable for these applications, particularly when followed by digital filtering that can provide additional frequency shaping.

Power Supply and Motor Drive Applications

Power supply filtering presents demanding requirements for current handling, efficiency, and EMI suppression that often favor LC filter implementations. Switch-mode power supplies generate high-frequency switching noise that requires effective attenuation while maintaining low conduction losses. LC filters can handle the high currents typical of power applications while providing minimal voltage drop and excellent high-frequency rejection.

Motor drive applications face similar challenges with the additional requirement for common-mode noise suppression, which LC filters address through specialized inductor designs featuring multiple windings or common-mode chokes. The ability to design LC filters for specific impedance characteristics enables optimal matching to motor and cable parameters, maximizing filtering effectiveness while minimizing system losses.

EMI compliance requirements in power applications often necessitate the superior attenuation capabilities of LC filters to meet regulatory standards while maintaining acceptable system efficiency. The conducted emissions limits specified by various international standards require filter designs capable of achieving 40-60dB of attenuation at specific frequencies, performance levels that are difficult to achieve with RC configurations alone.

Advanced Design Techniques and Optimization

Multi-Stage Filter Design

Advanced filtering applications often require multi-stage designs that combine the advantages of both LC and RC topologies to achieve optimal performance. Hybrid approaches might utilize LC stages for sharp cutoff characteristics followed by RC stages for additional attenuation and stability. This combination can provide the selectivity of LC filters while benefiting from the predictable behavior and cost-effectiveness of RC implementations.

Cascaded filter designs must account for inter-stage loading effects and impedance matching to prevent performance degradation. LC sections can be designed with specific characteristic impedances to provide proper termination for preceding stages, while RC sections require careful consideration of output impedance effects on subsequent stages. Buffer amplifiers may be necessary between stages to maintain performance specifications.

Component optimization in multi-stage designs involves balancing performance requirements against cost and complexity constraints. Higher-order responses can be achieved through multiple RC sections, potentially eliminating the need for expensive inductors while still meeting application requirements. However, the increased component count and cumulative tolerances must be weighed against the benefits of simpler individual stage designs.

Simulation and Modeling Approaches

Modern design tools enable accurate simulation of both LC and RC filter responses, including parasitic effects and component non-idealities that significantly impact real-world performance. SPICE modeling can reveal resonances, stability issues, and temperature effects that might not be apparent from ideal calculations. These tools are particularly valuable for LC designs where component parasitics can create unexpected resonances or instabilities.

Monte Carlo analysis capabilities allow designers to evaluate performance variations due to component tolerances, providing statistical confidence in meeting specifications across production variations. This analysis is particularly important for LC filters where resonant behavior can amplify the effects of component variations, potentially causing significant performance shifts in manufactured units.

Electromagnetic simulation tools become essential for LC filter designs operating at higher frequencies where parasitic coupling and radiation effects can significantly impact performance. Three-dimensional field solvers can predict these effects during the design phase, enabling layout optimization that minimizes unwanted interactions and ensures predicted performance in the final implementation.

FAQ

What are the main advantages of LC filters over RC filters?

LC filters offer several key advantages including much lower insertion loss in the passband, steeper roll-off characteristics (typically 40dB per decade versus 20dB for RC), and the ability to handle higher current levels without power dissipation. They also provide better impedance matching capabilities and can achieve higher Q factors for more selective filtering. However, these advantages come at the cost of increased complexity, size, and expense compared to RC implementations.

When should I choose an RC filter instead of an LC filter?

RC filters are preferred when cost, simplicity, and board space are primary concerns, or when the application can tolerate the gentler roll-off characteristics and higher insertion loss. They excel in applications requiring stable, predictable performance across temperature variations and are ideal for high-volume manufacturing due to standard component availability. RC filters are also better suited for low-power signal conditioning applications where the resistive losses are acceptable.

How do component tolerances affect LC versus RC filter performance?

LC filters are generally more sensitive to component tolerances due to their resonant behavior, where variations in L or C values can significantly shift the cutoff frequency and alter the response shape. A 5% tolerance in components can result in substantial performance variations in high-Q LC designs. RC filters demonstrate better tolerance immunity because their gradual roll-off characteristics are less sensitive to precise component values, making them more predictable in mass production.

Can LC and RC topologies be combined in a single filter design?

Yes, hybrid designs combining LC and RC sections can provide optimal performance for specific applications. For example, an LC input stage might provide sharp initial filtering and impedance matching, followed by RC stages for additional attenuation and stability. This approach can capture the benefits of both topologies while managing cost and complexity. However, careful attention to inter-stage impedance matching and loading effects is essential to maintain overall performance specifications.