The evolution of wireless communication systems has driven unprecedented demand for sophisticated frequency control components, particularly in the realm of high-frequency signal processing. Modern microwave resonator filter technology represents a critical foundation for next-generation telecommunications, radar systems, and satellite communications infrastructure. These precision-engineered components enable selective frequency transmission while maintaining exceptional signal integrity across demanding operating environments. As industry requirements continue to evolve toward higher frequencies and tighter performance specifications, understanding the latest developments in resonator filter design becomes essential for engineers and system integrators seeking optimal performance solutions.

Fundamental Principles of Microwave Resonator Technology

Electromagnetic Resonance Mechanisms

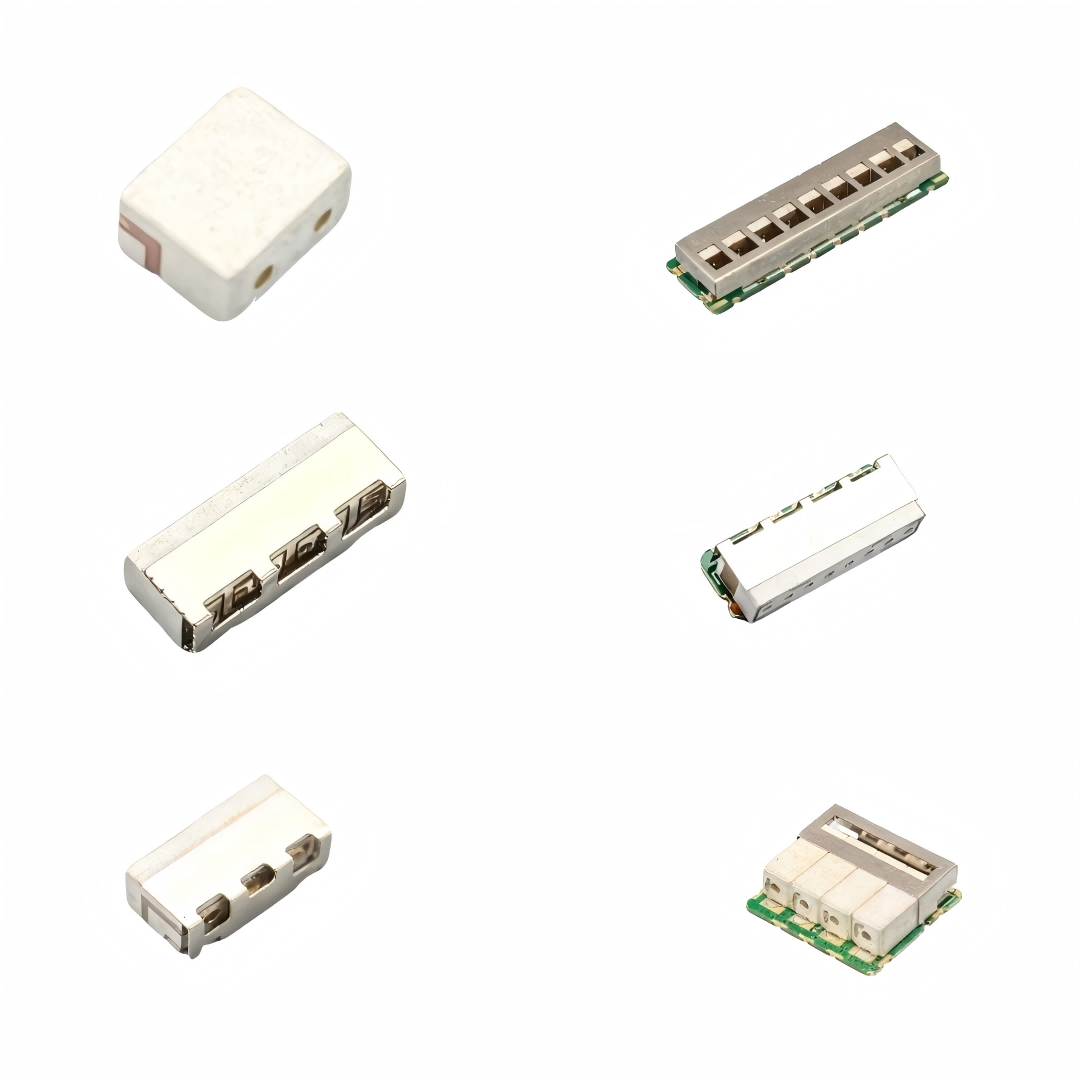

The underlying physics of microwave resonator filters relies on electromagnetic field confinement within carefully designed cavity structures or dielectric materials. When electromagnetic waves encounter these resonant structures, specific frequencies experience constructive interference, creating standing wave patterns that enhance signal transmission at desired frequencies while attenuating unwanted spectral components. This selective frequency response emerges from the geometric dimensions and material properties of the resonator, which determine the fundamental resonant frequency and associated harmonic modes.

Advanced resonator designs leverage multiple coupling mechanisms to achieve complex frequency responses, including magnetic coupling through shared magnetic fields, electric coupling via shared electric fields, and mixed coupling that combines both interaction types. The strength and nature of these coupling mechanisms directly influence the filter's bandwidth, insertion loss, and rejection characteristics. Modern microwave resonator filter implementations often incorporate multiple resonant elements arranged in sophisticated topologies to realize steep roll-off characteristics and deep rejection levels required for contemporary communication systems.

Material Selection and Dielectric Properties

The choice of resonator materials significantly impacts filter performance across multiple parameters including temperature stability, power handling capability, and overall size constraints. High-Q dielectric materials such as ceramic compounds offer exceptional temperature coefficient stability and low loss tangent values, making them ideal for precision frequency control applications. These materials typically feature dielectric constants ranging from 10 to 100, enabling substantial size reduction compared to air-filled cavity alternatives while maintaining excellent electrical performance.

Recent advances in material science have introduced novel ceramic compositions that combine ultra-low loss characteristics with exceptional thermal stability. These next-generation materials enable microwave resonator filter designs to achieve loaded Q factors exceeding 10,000 while maintaining frequency stability better than ±10 parts per million across industrial temperature ranges. Such performance levels directly translate to improved system selectivity, reduced phase noise, and enhanced overall communication quality in demanding applications.

Contemporary Design Methodologies and Simulation Techniques

Computer-Aided Design Evolution

Modern microwave resonator filter development relies heavily on sophisticated electromagnetic simulation software that enables precise prediction of electrical performance before physical prototyping. Three-dimensional finite element analysis tools now provide detailed visualization of electromagnetic field distributions within complex resonator geometries, allowing designers to optimize coupling mechanisms and minimize spurious resonances. These simulation capabilities have revolutionized the design process by reducing development cycles and enabling exploration of innovative topologies that would be impractical to evaluate through traditional analytical methods.

Advanced simulation techniques incorporate realistic material properties, manufacturing tolerances, and environmental effects to predict actual performance with remarkable accuracy. Multi-physics modeling capabilities now allow simultaneous analysis of electromagnetic, thermal, and mechanical effects, providing comprehensive understanding of filter behavior under real-world operating conditions. This holistic approach enables designers to optimize performance while ensuring reliability and manufacturability across diverse application requirements.

Artificial Intelligence Integration

The integration of machine learning algorithms into microwave resonator filter design represents a paradigm shift toward automated optimization and intelligent parameter selection. Neural network-based design tools can rapidly explore vast parameter spaces to identify optimal resonator configurations that meet specific performance targets while satisfying practical constraints. These AI-driven approaches significantly accelerate the design process and often discover novel solutions that might not be apparent through conventional design methodologies.

Deep learning models trained on extensive databases of measured filter performance can predict electrical characteristics with exceptional accuracy, enabling rapid prototyping and reducing the need for iterative physical testing. Furthermore, reinforcement learning algorithms can continuously improve design recommendations based on manufacturing feedback and field performance data, creating self-improving design systems that become more effective over time.

Emerging Applications and Market Trends

5G Infrastructure Requirements

The deployment of fifth-generation wireless networks has created unprecedented demand for high-performance microwave resonator filters capable of operating across millimeter-wave frequency bands. These systems require filters with extremely tight frequency selectivity to enable efficient spectrum utilization while minimizing interference between adjacent channels. The challenging requirements of 5G infrastructure include operation at frequencies exceeding 28 GHz, ultra-low insertion loss to preserve system sensitivity, and exceptional linearity to handle high signal power levels without generating intermodulation distortion.

Massive MIMO antenna systems employed in 5G base stations require arrays of precisely matched filters to maintain beam steering accuracy and optimize spatial diversity performance. This application demands exceptional filter-to-filter consistency and long-term stability to ensure reliable network operation across diverse environmental conditions. The economic pressures of large-scale deployment also emphasize the importance of cost-effective manufacturing approaches that can deliver premium performance at competitive price points.

Satellite Communication Evolution

Next-generation satellite communication systems are driving innovation in lightweight, compact microwave resonator filter designs optimized for space applications. Low Earth Orbit constellations require thousands of satellites, each equipped with multiple filters for frequency management and interference suppression. These space-qualified components must survive launch stresses, operate reliably in vacuum environments, and maintain stable performance across extreme temperature variations encountered in orbital operations.

Advanced satellite systems increasingly utilize adaptive filtering capabilities that can dynamically adjust frequency response characteristics based on real-time interference conditions or changing communication requirements. This flexibility demands sophisticated filter architectures that combine traditional resonator elements with electronically tunable components, creating hybrid solutions that offer both high performance and operational versatility.

Manufacturing Innovations and Quality Control

Precision Manufacturing Techniques

Contemporary microwave resonator filter manufacturing employs advanced production techniques that achieve dimensional tolerances measured in micrometers, ensuring consistent electrical performance across large production volumes. Computer-controlled machining centers utilize diamond-tipped cutting tools and precision measurement systems to create resonator cavities with surface finishes approaching optical quality levels. These manufacturing capabilities enable production of filters with extremely tight frequency tolerances and exceptional unit-to-unit consistency.

Additive manufacturing technologies are beginning to influence microwave resonator filter production, particularly for complex internal geometries that would be difficult or impossible to create through conventional machining processes. Three-dimensional printing of ceramic materials and subsequent sintering processes can produce intricate coupling structures and integrated resonator arrays in single manufacturing steps. While still emerging, these technologies promise to enable entirely new filter architectures and potentially reduce production costs for specialized applications.

Automated Testing and Characterization

Modern quality assurance processes for microwave resonator filters incorporate automated test equipment that can rapidly characterize electrical performance across multiple parameters simultaneously. Vector network analyzers integrated with robotic handling systems enable high-throughput testing of filter frequency response, insertion loss, return loss, and group delay characteristics. Statistical process control algorithms continuously monitor production data to identify trends and potential quality issues before they impact delivered products.

Advanced measurement techniques now include time-domain analysis capabilities that can identify and locate defects within filter structures based on reflection signatures. These diagnostic capabilities enable rapid identification of manufacturing anomalies and facilitate continuous improvement of production processes. Real-time feedback systems can automatically adjust manufacturing parameters to compensate for detected variations, maintaining consistent product quality throughout extended production runs.

Future Technological Developments

Quantum-Enhanced Filter Design

Research into quantum-enhanced microwave resonator filter technology explores the potential for leveraging quantum mechanical effects to achieve performance levels beyond classical limitations. Quantum coherence effects in specially designed resonator structures might enable ultra-low noise filtering applications and enhanced sensitivity for weak signal detection. While still in early research phases, these concepts could eventually lead to revolutionary advances in filter technology for specialized scientific and defense applications.

Quantum sensing techniques are also being investigated as tools for precision characterization of microwave resonator filter performance. These measurement approaches could provide unprecedented accuracy in determining filter parameters and enable detection of subtle performance variations that are currently beyond the resolution of conventional test equipment. Such capabilities would support development of even more demanding applications requiring extreme performance specifications.

Metamaterial Integration

The integration of metamaterial concepts into microwave resonator filter design opens possibilities for achieving exotic electromagnetic properties not available in conventional materials. Artificially structured materials with engineered electromagnetic properties can create resonator elements with enhanced field confinement, reduced physical size, or novel frequency response characteristics. These metamaterial-enhanced filters could enable compact designs with performance levels previously achievable only in much larger conventional implementations.

Metamaterial structures also offer potential for creating tunable microwave resonator filter designs where electromagnetic properties can be dynamically adjusted through external control signals. Such adaptive filtering capabilities would enable reconfigurable communication systems that can optimize performance for changing operational requirements or environmental conditions. The combination of metamaterial concepts with traditional resonator design principles represents a promising avenue for next-generation filter technology development.

FAQ

What factors determine the operating frequency range of a microwave resonator filter

The operating frequency range of a microwave resonator filter is primarily determined by the physical dimensions of the resonant structure and the electromagnetic properties of the materials used in its construction. The fundamental resonant frequency is inversely proportional to the square root of the product of the effective permittivity and permeability of the resonator medium, while the physical length or volume of the resonator provides the primary frequency-setting parameter. Higher-order modes and harmonic responses extend the usable frequency range beyond the fundamental resonance, though with different performance characteristics.

How do temperature variations affect microwave resonator filter performance

Temperature variations impact microwave resonator filter performance through multiple mechanisms including thermal expansion of resonator dimensions, temperature-dependent changes in material dielectric properties, and thermal stress effects that can alter mechanical coupling between filter elements. High-quality ceramic dielectric materials are specifically engineered to minimize temperature coefficient effects, typically achieving frequency stability better than 10 parts per million per degree Celsius. Advanced filter designs incorporate temperature compensation techniques such as bimetallic adjustment mechanisms or materials with opposing temperature coefficients to maintain stable performance across operating temperature ranges.

What are the key performance metrics used to evaluate microwave resonator filter quality

Key performance metrics for microwave resonator filter evaluation include insertion loss, which measures signal attenuation within the passband; return loss, which quantifies impedance matching quality; rejection levels, which specify attenuation of unwanted frequencies; bandwidth characteristics including 3dB bandwidth and shape factor; group delay variation across the passband; and unloaded Q factor, which indicates resonator efficiency. Power handling capability, temperature stability, and spurious response suppression are additional critical parameters that determine filter suitability for specific applications. Advanced applications may also require evaluation of intermodulation distortion, phase noise contribution, and long-term stability characteristics.

How do manufacturing tolerances impact microwave resonator filter performance consistency

Manufacturing tolerances directly influence microwave resonator filter performance consistency by affecting resonant frequencies, coupling strengths, and impedance matching characteristics. Dimensional variations as small as a few micrometers can cause measurable frequency shifts in high-frequency applications, while surface finish variations impact unloaded Q factors and insertion loss performance. Modern manufacturing processes employ statistical process control and automated measurement techniques to maintain tolerances within acceptable limits, while design techniques such as post-manufacturing tuning and tolerance-insensitive topologies help minimize the impact of unavoidable manufacturing variations on final filter performance.

Table of Contents

- Fundamental Principles of Microwave Resonator Technology

- Contemporary Design Methodologies and Simulation Techniques

- Emerging Applications and Market Trends

- Manufacturing Innovations and Quality Control

- Future Technological Developments

-

FAQ

- What factors determine the operating frequency range of a microwave resonator filter

- How do temperature variations affect microwave resonator filter performance

- What are the key performance metrics used to evaluate microwave resonator filter quality

- How do manufacturing tolerances impact microwave resonator filter performance consistency