Understanding the fundamental principles behind microwave dielectric ceramic filter technology requires examining the unique electromagnetic properties of ceramic materials. These sophisticated components play a crucial role in modern telecommunications, wireless networks, and high-frequency electronic systems by providing precise frequency selection and signal filtering capabilities. The ceramic filter technology has evolved significantly over the past decades, offering superior performance characteristics compared to traditional metallic waveguide filters.

Ceramic materials exhibit exceptional dielectric properties that make them ideal for microwave applications. These materials demonstrate low loss tangent values, high dielectric constants, and excellent temperature stability across wide frequency ranges. The ceramic substrate acts as a resonant cavity where electromagnetic energy can be stored and manipulated according to specific design parameters. This foundational understanding enables engineers to develop highly selective filtering solutions for demanding applications.

Fundamental Operating Principles

Dielectric Resonance Mechanisms

The core operational principle of ceramic filters relies on dielectric resonance within the ceramic material itself. When electromagnetic waves propagate through the ceramic medium, they interact with the material's atomic structure, creating standing wave patterns at specific resonant frequencies. The dielectric constant of the ceramic material determines the wavelength compression factor, allowing for compact filter designs while maintaining excellent electrical performance.

The resonant frequency depends directly on the physical dimensions of the ceramic element and its dielectric properties. Engineers can precisely control these parameters during manufacturing to achieve desired center frequencies and bandwidth characteristics. The quality factor, or Q-factor, of ceramic resonators typically exceeds values achievable with conventional metallic cavities, resulting in sharper filter responses and lower insertion losses.

Electromagnetic Field Distribution

Within a ceramic filter structure, electromagnetic fields concentrate primarily in the high-dielectric-constant ceramic material while exhibiting exponential decay in surrounding air or low-dielectric regions. This field confinement effect enables multiple resonant modes to coexist within a single ceramic block, facilitating the implementation of multi-pole filter responses in compact form factors.

The boundary conditions at ceramic-air interfaces create specific field patterns that determine coupling strengths between adjacent resonators. By carefully controlling these coupling mechanisms through geometric design variations, filter engineers can realize complex transfer functions including Chebyshev, Butterworth, and elliptic responses. The three-dimensional nature of field distributions in ceramic structures provides additional degrees of freedom compared to planar filter technologies.

Design Configuration Methods

Single-Mode Resonator Structures

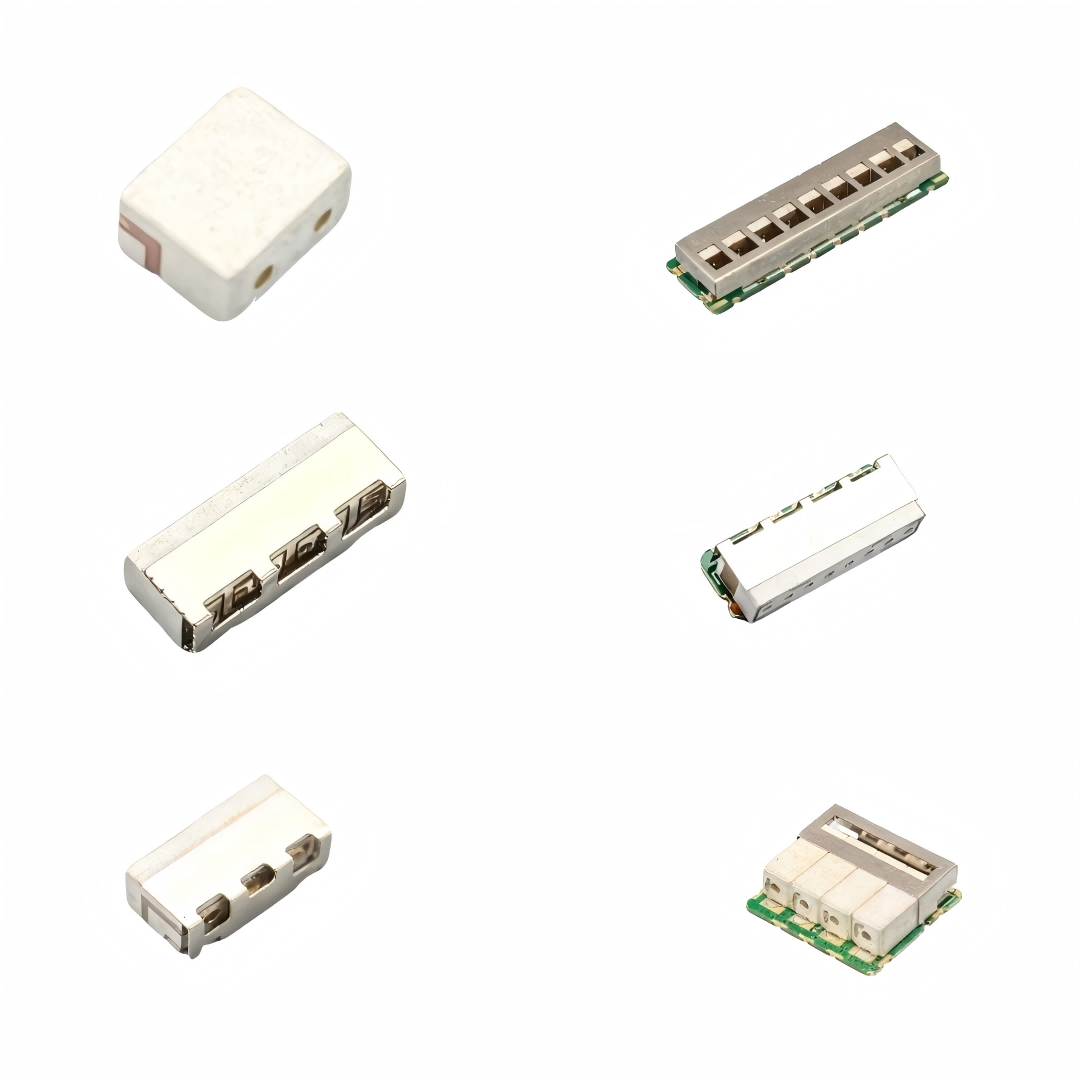

Single-mode ceramic resonators form the building blocks of more complex filter architectures. These elements typically feature cylindrical or rectangular geometries with carefully dimensioned proportions to support the desired fundamental resonant mode while suppressing unwanted higher-order modes. The aspect ratio and overall size determine the operational frequency range and unloaded quality factor.

Input and output coupling to single-mode resonators can be achieved through various methods including probe coupling, loop coupling, or aperture coupling. Each coupling mechanism offers different bandwidth and impedance matching characteristics, allowing designers to optimize performance for specific application requirements. The coupling strength directly influences the filter's bandwidth and in-band ripple characteristics.

Multi-Mode Filter Architectures

Advanced ceramic filter designs exploit multiple resonant modes within a single ceramic block to achieve higher-order filter responses with reduced component count. Dual-mode and triple-mode configurations are commonly employed in applications requiring steep skirt selectivity and high isolation between passbands and stopbands. These designs require sophisticated electromagnetic modeling to predict and control mode coupling effects.

The implementation of cross-coupling between non-adjacent modes enables the realization of transmission zeros in the filter response, significantly improving rejection characteristics. This technique is particularly valuable in applications where stringent spurious signal suppression is required, such as satellite communication systems and radar applications. Proper mode degeneracy control ensures stable performance across temperature and manufacturing variations.

Manufacturing Process Considerations

Ceramic Material Selection

The selection of appropriate ceramic materials represents a critical factor in microwave dielectric ceramic filter performance optimization. Common materials include barium titanate-based compositions, aluminum oxide ceramics, and specialized low-loss dielectric formulations. Each material system offers distinct advantages in terms of dielectric constant, temperature coefficient, and processing characteristics.

Material purity and grain structure uniformity directly impact the achievable quality factor and long-term stability of ceramic filters. Advanced processing techniques including controlled atmosphere sintering and hot isostatic pressing help achieve optimal microstructural properties. The temperature coefficient of resonant frequency must be carefully controlled through material composition adjustments to ensure stable operation across specified temperature ranges.

Precision Machining and Tuning

Manufacturing tolerances in ceramic filter production require extreme precision to achieve specified electrical performance. Modern computer-controlled machining centers enable dimensional accuracies within micrometers, ensuring consistent resonant frequencies across production batches. Surface finish quality affects both electrical losses and long-term reliability of ceramic filter assemblies.

Post-manufacturing tuning procedures allow for fine adjustment of filter characteristics to compensate for material and dimensional variations. Tuning methods include selective material removal, metallic loading, or mechanical adjustment of coupling elements. Automated tuning systems using network analyzer feedback enable rapid optimization of filter responses to meet stringent specification requirements.

Performance Characteristics Analysis

Frequency Response Properties

Ceramic filters exhibit exceptional frequency selectivity characteristics due to the high quality factor of dielectric resonators. Typical unloaded Q-values range from several hundred to over ten thousand, depending on the ceramic material and operating frequency. This high-Q behavior translates to sharp filter skirts and low insertion loss within the passband region.

The temperature stability of ceramic filters surpasses that of many alternative technologies, with frequency drift coefficients typically maintained below 50 parts per million per degree Celsius. This stability is achieved through careful material selection and compensation techniques that minimize the net temperature coefficient of the complete filter assembly. Long-term aging effects are minimal due to the stable crystalline structure of ceramic materials.

Power Handling Capabilities

Ceramic materials demonstrate excellent power handling capabilities in microwave applications, with typical power ratings exceeding several hundred watts for communication-grade filters. The thermal conductivity of ceramic substrates enables efficient heat dissipation, preventing localized heating that could lead to performance degradation or permanent damage.

Power handling limitations are typically determined by the breakdown strength of air gaps or coupling elements rather than the ceramic material itself. Proper design of high-field regions and selection of appropriate coupling mechanisms ensure reliable operation at maximum specified power levels. Pulse power handling capabilities often exceed continuous wave ratings by significant margins due to the thermal mass of ceramic structures.

Application Areas and Implementation

Telecommunications Infrastructure

Modern cellular base stations rely heavily on ceramic filter technology to achieve the stringent selectivity requirements of multi-band communication systems. These filters enable efficient spectrum utilization by providing high isolation between adjacent frequency bands while maintaining low insertion loss in desired signal paths. The compact size and high performance of ceramic filters make them ideal for space-constrained installations.

Satellite communication systems utilize ceramic filters for both ground-based and space-borne applications where reliability and performance stability are paramount. The radiation resistance and temperature stability of ceramic materials make them suitable for harsh operating environments encountered in satellite systems. Advanced designs incorporate redundancy and graceful degradation characteristics to ensure continued operation even under component stress conditions.

Radar and Defense Applications

Military and aerospace radar systems demand exceptional filter performance to achieve the sensitivity and resolution required for modern applications. Ceramic filters provide the necessary dynamic range and spurious signal rejection to enable detection of weak targets in the presence of strong interference signals. The wide instantaneous bandwidth capabilities of ceramic filter designs support advanced radar waveforms and signal processing techniques.

Electronic warfare systems employ ceramic filters for both signal reception and transmission path filtering. The ability to customize filter responses for specific threat scenarios while maintaining broadband compatibility makes ceramic technology particularly valuable in adaptive and software-defined radio architectures. The inherent linearity of ceramic resonators minimizes intermodulation distortion in multi-signal environments.

FAQ

What are the main advantages of ceramic filters compared to metal cavity filters

Ceramic filters offer several key advantages including significantly smaller size and weight, higher quality factors leading to better selectivity, superior temperature stability, and lower manufacturing costs for high-volume applications. The dielectric loading effect allows for substantial size reduction while maintaining excellent electrical performance, making ceramic filters ideal for applications where space and weight are critical considerations.

How do environmental conditions affect ceramic filter performance

Environmental factors such as temperature, humidity, and vibration have minimal impact on properly designed ceramic filters. The temperature coefficient can be controlled through material selection and compensation techniques to maintain frequency stability within specified limits. Ceramic materials are inherently resistant to humidity effects and mechanical stress, providing reliable operation across wide environmental ranges typical of telecommunications and aerospace applications.

Can ceramic filters be customized for specific frequency requirements

Yes, ceramic filters can be fully customized to meet specific frequency, bandwidth, and response shape requirements through careful design of resonator dimensions, coupling mechanisms, and overall filter topology. Modern electromagnetic simulation tools enable precise prediction of filter performance, allowing engineers to optimize designs for particular applications while minimizing development time and manufacturing costs.

What maintenance requirements do ceramic filters have in operational systems

Ceramic filters require minimal maintenance due to the stable nature of ceramic materials and the absence of moving parts or degradable components. Routine performance verification through periodic testing is typically the only maintenance requirement. The long-term stability and reliability of ceramic filters make them particularly suitable for remote installations and applications where maintenance access is limited or costly.