Modern elektronik ve sinyal işleme uygulamalarında, istenmeyen düşük frekanslı bileşenleri süzerek yüksek frekanslı sinyalleri korumak önemli bir zorluk olmaya devam etmektedir. LC yüksek geçiren filtre, devrelerinden gürültüyü, DC ofseti ve diğer düşük frekanslı girişimleri ortadan kaldırmak isteyen mühendisler için en etkili pasif süzgeç çözümlerinden biridir. Bu tür filtrelerin temel prensiplerini anlamak, mühendislerin çeşitli endüstriyel uygulamalarda sinyal bütünlüğünü koruyan sağlam sistemler tasarlamasına olanak tanır.

Yüksek geçiren filtreleme devrelerindeki bobinlerin ve kondansatörlerin yapısı, önceden belirlenmiş bir kesim frekansının altındaki sinyalleri doğal olarak zayıflatan, frekansa bağlı empedans karakteristikleri oluşturur. Bu seçici filtreleme davranışı, frekans ayrımının genel sistem performansını belirlediği telekomünikasyon, ses işleme ve güç elektroniğinde LC devrelerini vazgeçilmez hale getirir. Modern filtre tasarımı, optimal sonuçlara ulaşmak için bileşen toleranslarının, sıcaklık kararlılığının ve üretim sınırlamalarının dikkatlice değerlendirilmesini gerektirir.

Temel Devre Teorisi ve Bileşen Davranışı

Yüksek Geçiren Uygulamalarda Bobin Özellikleri

Endüktanslar, sinyal frekansı ile orantılı olarak artan frekansa bağımlı empedansa sahiptir ve bu nedenle düşük frekanslı içerikleri engellemek, yüksek frekanslı sinyallerin ise minimum zayıflama ile geçmesine izin vermek için onları ideal bileşenler haline getirir. Endüktif reaktans formülü XL = 2πfL, empedansın frekansla birlikte nasıl doğrusal olarak arttığını göstererek yüksek geçiren filtre davranışının temelini oluşturur. Kalite faktörü hususları, endüktans seçiminde kritik hale gelir çünkü kaçak direnç ve çekirdek kayıpları, hedef frekanslarda filtrenin performansını önemli ölçüde etkileyebilir.

Sıcaklık katsayısı kararlılığı ve doyum akımı değerleri, belirli uygulamalar için endüktans seçimini doğrudan etkiler. Ferrit çekirdekli endüktanslar, minimum kayıpla mükemmel yüksek frekans performansı sunarken, havanın çekirdek yaptığı tasarımlar üstün doğrusallık sağlar ancak daha büyük fiziksel alan kaplar. Bu tür uzlaşım durumlarının anlaşılması, mühendislerin sistemlerini optimize etmelerini sağlar. lc yüksek geçiren filtre özel performans gereksinimleri ve çevresel kısıtlamalar için tasarlanmıştır.

Kondansatör Seçimi ve Frekans Tepkisi

Kapasitif reaktans, XC = 1/(2πfC) formülüne göre frekansla ters orantılı olarak azalır ve etkili yüksek geçiren filtreleme için gerekli olan tamamlayıcı empedans karakteristiğini oluşturur. Bu frekansa bağlı davranış, kondansatörlerin düşük frekanslı sinyallere yüksek empedans sunarken yüksek frekanslı bileşenlere düşük empedanslı yollar sağlamasına olanak tanır. Dielektrik malzeme seçimi, zorlu uygulamalarda sıcaklık stabilitesi, voltaj dayanımı ve uzun vadeli güvenilirlik üzerinde önemli bir etkiye sahiptir.

Seramik kapasitörler, düşük eşdeğer seri direnç ile birlikte mükemmel yüksek frekans performansı sunar ve minimum eklenme kaybının kritik olduğu zorlu filtreleme uygulamaları için uygun hale getirir. Film kapasitörler üstün doğrusallık ve kararlılık sunar ancak çok yüksek frekanslarda daha yüksek kaçak endüktans gösterme eğiliminde olabilir. Mühendisler, pratik filtre çözümleri geliştirirken bu özellikleri maliyet ve boyut kısıtlamalarına karşı dikkatlice dengelemelidir.

Tasarım Metodolojileri ve Hesaplama Teknikleri

Kesim Frekansının Belirlenmesi

Bir LC yüksek geçiren filtrenin kesim frekansı, tasarım süreci sırasında seçilen devre topolojisine ve bileşen değerlerine bağlıdır. Basit LC yapıları için endüktans, kapasitans ve kesim frekansı arasındaki ilişki, hassas frekans yanıtı tahmini yapılmasını sağlayan iyi kurulmuş matematiksel ilkeleri takip eder. Mühendisler genellikle sinyal genliğinin maksimum değerinin yaklaşık %70.7'sine düştüğü -3 dB noktasını nominal kesim frekansı olarak hedefler.

Gelişmiş tasarım teknikleri, daha dik yuvarlanma karakteristikleri ve gelişmiş durdurma bandı reddi elde etmek için çoklu kutuplar ve sıfırlar içerir. Chebyshev ve Butterworth cevap şekilleri, geçiş bandı dalgalanması ile geçiş bandı eğimliği arasında farklı ödünler sunarak mühendislere belirli uygulama gereksinimleri için filtre performansını iyileştirme imkanı verir. Bilgisayar destekli tasarım araçları, matematiksel doğruluğu korurken karmaşık filtre ağlarının hızlı tekrarı ve optimizasyonunu kolaylaştırır.

Empedans Uygunluğu Hususları

Uygun empedans eşleştirme, filtre aşamaları ile bağlı devreler arasında maksimum güç transferini sağlarken sistemin genel performansını düşürebilecek yansıtmaları en aza indirir. Kaynak ve yük empedansları, belirlenen performans hedeflerine ulaşmak için tasarım aşamasında dikkatle ele alınması gereken filtre tepki karakteristiklerini önemli ölçüde etkiler. Uyumsuz empedanslar, frekans yanıtı değişikliklerine, eklenim kaybının artmasına ve hassas uygulamalarda olası kararsızlık sorunlarına neden olabilir.

Transformatör kuplajı ve empedans ölçekleme teknikleri, mühendislerin elektriksel performansta ödün vermeden farklı sistem empedans seviyeleri için filtre tasarımlarını uyarlamasına olanak tanır. Dengeli ve dengesiz yapılandırmalar, empedans uyumlandırması için farklı yaklaşımlar gerektirir; dengeli tasarımlar birçok uygulamada üstün ortak kip rejeksiyonu ve gürültü bağışıklığı sunar. Bu prensipleri anlamak, mühendislerin değişken çalışma koşullarında performansını koruyan sağlam filtre çözümleri geliştirmesine yardımcı olur.

Uygulamaya Geçirme ve İmalat Hususları

Bileşen Tolerans Analizi

İndüktörlerde ve kapasitörlerde imalat toleransları, uygulanan LC yüksek geçiren filtre devrelerinin gerçek kesim frekansını ve tepki şeklini doğrudan etkiler. Standart bileşen toleransları genellikle %5 ile %20 arasında değişir ve üretim partileri boyunca en kötü durum performans değişimlerini tahmin etmek için istatistiksel analiz gerekir. Monte Carlo simülasyon teknikleri, mühendislerin bileşen varyasyonlarının filtrenin genel performansını nasıl etkilediğini anlamasına ve uygun tasarım payları oluşturmasına yardımcı olur.

İndüktörler ile kapasitörler arasındaki sıcaklık katsayısının eşleştirilmesi, çalışma sıcaklık aralıklarında frekans kaymasını en aza indirgeyerek uzun vadeli stabiliteyi artırır ve ayarlama veya kalibrasyon işlemlerine olan ihtiyacı azaltır. Daha dar toleranslara sahip hassas bileşenler üretim maliyetlerini artırır ancak sıkı frekans doğruluğu ve tekrarlanabilirliği gerektiren uygulamalarda gerekli olabilir. Maliyet-fayda analizi, bileşen hassasiyeti ile sistem gereksinimleri arasındaki optimal dengenin belirlenmesine yardımcı olur.

Düzen ve Kaçak Yönetimi

Fiziksel düzen, yüksek frekanslı performansı, tasarlanan filtre özelliklerini değiştirebilen kaçak endüktans, kapasitans ve direnç yoluyla önemli ölçüde etkiler. Toprak düzlemi tasarımı, hat yönlendirmesi ve bileşen yerleştirme, yüksek çalışma frekanslarında giderek daha önemli hale gelen kaçak elemanlara katkıda bulunur. Döngü alanlarını en aza indirmek ve sinyal yollarında tutarlı empedansı korumak, amaçlanan filtre yanıtını korurken elektromanyetik girişime karşı duyarlılığı azaltmaya yardımcı olur.

Çok katmanlı baskılı devre panolarında via yerleşimi ve katman geçişleri, tasarım sürecinde dikkatlice modellenmesi ve telafi edilmesi gereken ek parasitik elemanlar ortaya çıkarır. Üç boyutlu elektromanyetik simülasyon araçları, mühendislerin bu etkileri prototip üretiminden önce tahmin etmesine ve en aza indirmesine olanak tanıyarak geliştirme süresini kısaltır ve ilk seferde başarılı sonuç alma oranını artırır. Bu fiziksel etkilerin anlaşılması, teorik filtre tasarımlarının pratik uygulamalara başarıyla aktarılmasını sağlar.

Performans Optimizasyonu ve Test Stratejileri

Ölçüm Teknikleri ve Doğrulama

Ağ analizörü ölçümleri, lc yüksek geçiren filtrenin tasarım özelliklerine karşı performansının doğrulanması için gerekli olan genlik, faz ve grup gecikmesi karakteristiklerini içeren kapsamlı frekans yanıtı karakterizasyonu sağlar. Uygun kalibrasyon prosedürleri ve ölçüm düzenekleri, sistematik hataları en aza indirerek doğru sonuçlar elde edilmesini sağlar ve tasarım eksikliklerini veya bileşen sorunlarını maskeleyebilecek etkileri önler. Zaman domeni ölçümleri, frekans domeni analizini tamamlayarak darbe ve dijital sinyal uygulamaları için önemli olan geçici davranış ve yerleşim karakteristiklerini ortaya çıkarır.

Çevresel testler, belirtilen sıcaklık, nem ve titreşim aralıklarında filtre performansını doğrular ve hedef uygulamalarda güvenilir çalışmayı sağlar. Hızlandırılmış yaşlanma testleri, olası başarısızlık modlarını önceden belirlemek ve uzun vadeli kararlılığı tahmin etmek için yardımcı olur. ürünler son kullanıcıları ulaşmak. Kapsamlı test protokolleri, filtre performansına güven oluştururken kalite kontrol ve üretim süreci optimizasyonu için gerekli verileri sağlar.

Belirli Uygulamalar için Optimizasyon

Farklı uygulamalar, eklem kaybı, durdurma bandı reddetme, grup gecikme değişimi ve fiziksel kısıtlamalar arasında denge kurarak benzersiz optimizasyon yaklaşımları gerektirir. Ses uygulamaları genellikle düşük bozulmaya ve minimum grup gecikme değişimine öncelik verirken, haberleşme sistemleri keskin geçiş karakteristiklerini ve yüksek durdurma bandı reddetmeyi vurgulayabilir. Güç elektroniği uygulamaları ise genellikle yüksek gerilim ve akım taşıma kapasitesine sahip, ancak aynı zamanda filtreleme etkinliğini koruyabilen sağlam tasarımlar gerektirir.

Elektromanyetik uyumluluk gereksinimleri, yayılan emisyonları en aza indirmek ve dış girişim kaynaklarına karşı bağışıklığı artırmak için belirli tasarım yaklaşımlarını belirleyebilir. Koruma teknikleri, bileşen seçimi ve yerleşim optimizasyonu, istenen filtreleme performansını korurken EMC uyumluluğunu sağlamaya katkıda bulunur. Bu uygulamaya özgü gereksinimleri anlamak, mühendislerin ilgili tüm şartname ve standartları karşılayan optimize edilmiş çözümler geliştirmelerini sağlar.

İleri Tasarım Kavramları ve Yeni Gelişmeler

Aktif-Pasif Hibrit Yaklaşımlar

Pasif LC elemanlarının aktif bileşenlerle birleştirilmesi, daha yüksek Q faktörleri, ayarlanabilir kesim frekansları ve giriş ile çıkış portları arasındaki yalıtımın iyileştirilmesi gibi gelişmiş performans özelliklerine sahip hibrit filtre tasarımlarının oluşturulmasını sağlar. İşlemsel amplifikatörler ve diğer aktif cihazlar, saf pasif yaklaşımlarla pratik olmayan veya gerçekleştirilemeyen transfer fonksiyonlarının gerçekleştirilmesini mümkün kılar. Bu hibrit tasarımlar, optimal performansı elde etmek için güç tüketimi, gürültü ve kararlılığın dikkatli bir şekilde değerlendirilmesini gerektirir.

Dijital olarak kontrol edilen analog filtreler, uyarlamalı uygulamalarda filtre özelliklerinin gerçek zamanlı olarak ayarlanmasına imkan tanıyan programlanabilir elemanlar içerir. Gerilim kontrollü kapasitörler, anahtarlamalı kapasitör dizileri ve dijital olarak kontrol edilen indüktörler, LC filtreleme yaklaşımının temel avantajlarını korurken dinamik filtre ayarlamasına olanak tanır. Bu esneklik, yazılım tanımlı radyo uygulamaları ve değişken frekans tepkimesi gerektiren diğer sistemlerde değer kazanır.

Küçültme ve Entegrasyon Stratejileri

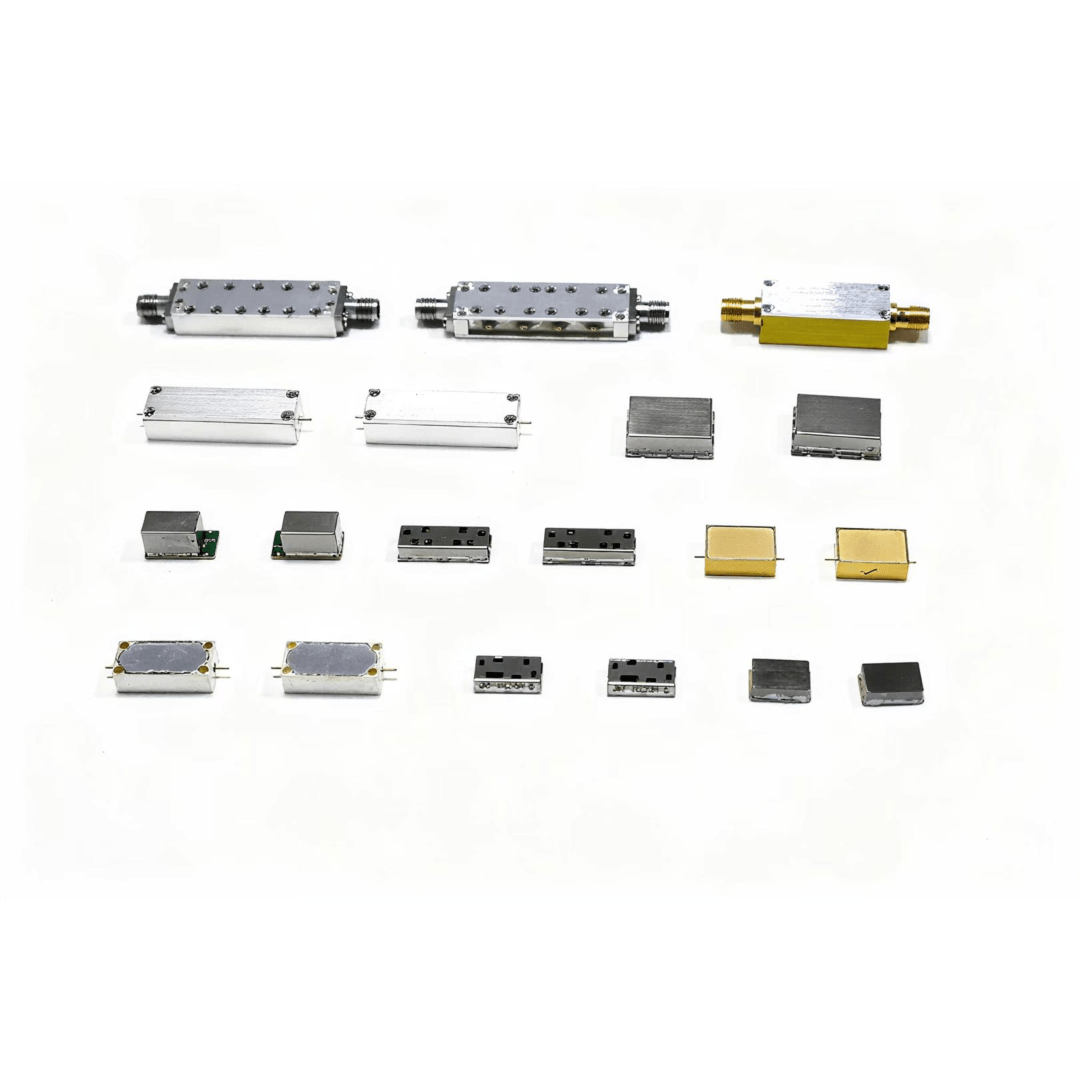

Entegre pasif devre teknolojisi, modern taşınabilir ve gömülü uygulamalara uygun küçük boyutlarda LC yüksek geçiren filtre devrelerinin gerçekleştirilmesine olanak tanır. İnce film ve kalın film üretim süreçleri, kesin bileşen değerlerine ve mükemmel eşleştirme özelliklerine izin verirken genel devre boyutunu ve ağırlığını azaltır. Sistem küçültme eğilimleri çeşitli sektörlerde devam ettikçe bu yaklaşımlar giderek daha önemli hale gelmektedir.

Üç boyutlu bileşen yerleşimleri ve gömülü pasif teknolojiler, elektriksel performansı korurken filtrelerin kapladığı alanı daha da azaltır. İleri düzey ambalajlama teknikleri, tek modüller içinde birden fazla filtre işlevinin entegre edilmesine olanak tanıyarak sistem tasarımını basitleştirir ve bağlantı noktalarının azalmasıyla güvenilirliği artırır. Bu ortaya çıkan teknolojilerin anlaşılması, mühendislerin gelecekteki tasarım zorluklarına ve fırsatlarına hazırlanmasına yardımcı olur.

SSS

Bir LC yüksek geçiren filtrenin kesim frekansını ne belirler

Kesim frekansı, filtre tasarımında kullanılan endüktans ve kapasitans değerlerine ve devre topolojisine bağlıdır. Basit LC yapıları için kesim frekansı, bileşen değerlerini istenen frekans tepkisiyle ilişkilendiren standart formüller kullanılarak hesaplanabilir. Çoklu kutuplara sahip daha karmaşık tasarımlar ise doğru tahmin için özel hesaplama tekniklerini ve bilgisayar destekli tasarım araçlarını gerektirir.

Bileşen toleransları filtre performansını nasıl etkiler

Standart bileşen toleransları, üretim partileri boyunca kabul edilebilir performansı sağlamak için tasarım paylarının gerekli kılınmasıyla, kesim frekansında ad nominal değerlerden %5-20'lik sapmalara neden olur. Sıcaklık katsayıları ve yaşlanma etkileri, uzun vadeli kararlılık gerektiren uygulamalar için dikkate alınması gereken ek değişkenlikler getirir. İstatistiksel analiz ve Monte Carlo simülasyonu, tasarım sürecinde en kötü durum performans değişimlerini tahmin etmeye yardımcı olur.

Aktif alternatiflere kıyasla LC filtrelerin temel avantajları nelerdir

LC yüksek geçiren filtreler, aktif filtre tasarımlarına kıyasla mükemmel doğrusallık, güç tüketimi gerektirmeme ve üstün yüksek frekanslı performans sunar. Yüksek sinyal seviyelerini bozulmadan işlerken doğası gereği kararlılık ve güvenilirlik sağlar. Bu özellikler, aktif filtrelerin pratik olmadığı güç elektroniği, RF uygulamaları ve diğer zorlu ortamlar için özellikle uygun hale getirir.

Fiziksel yerleşim, yüksek frekanslı filtre performansını nasıl etkiler

Yüksek frekanslarda fiziksel yerleşimden kaynaklanan kaçak endüktans, kapasitans ve direnç giderek daha belirgin hâle gelir ve tasarlanan filtre karakteristiklerini değiştirebilir. Uygun toprak düzlemi tasarımı, döngü alanlarının en aza indirilmesi ve dikkatli bileşen yerleştirme, istenen performansın korunmasına ve elektromanyetik girişimin azaltılmasına yardımcı olur. Üç boyutlu elektromanyetik simülasyon araçları, prototip üretimi öncesinde yerleşim etkilerinin optimize edilmesine imkan tanır.