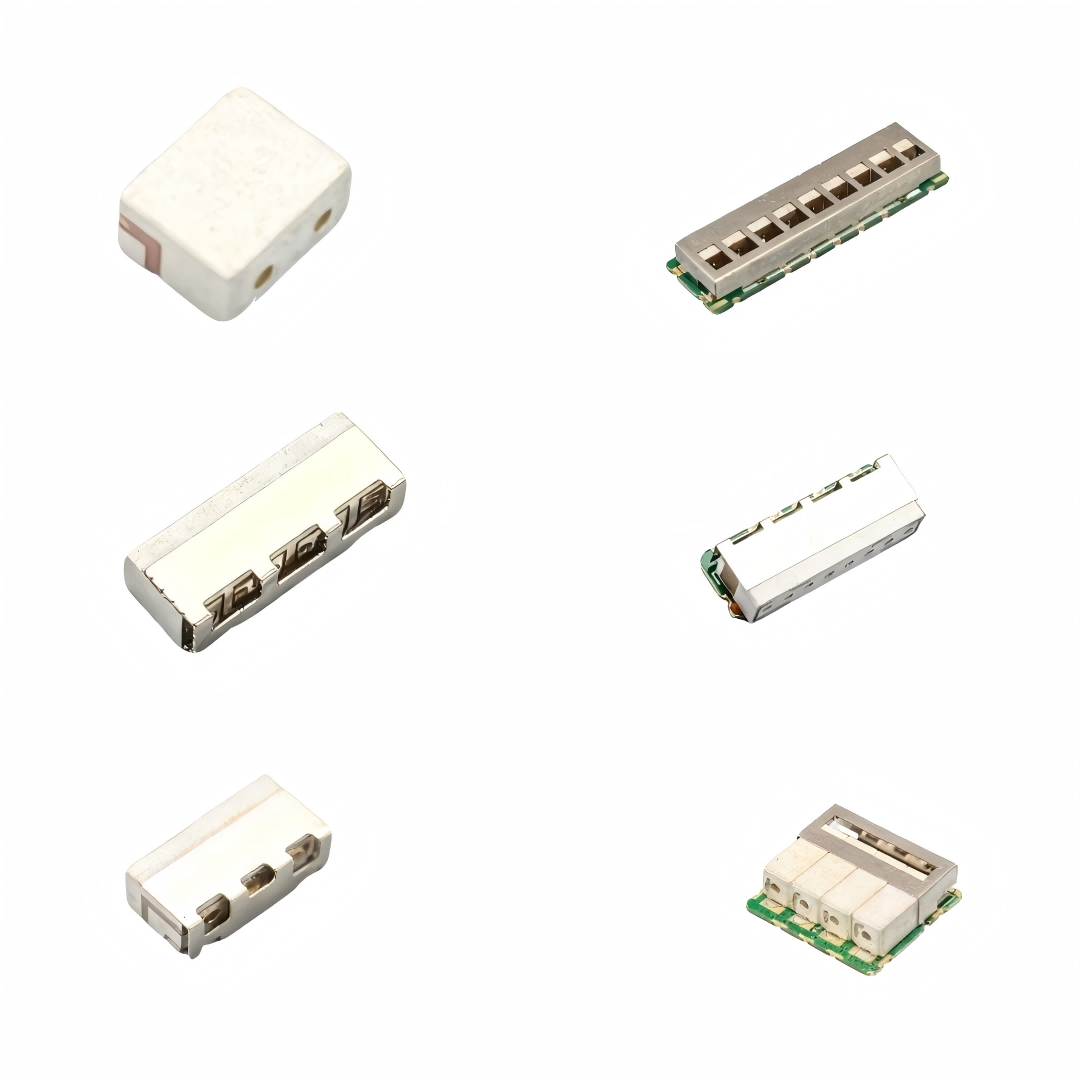

Modern wireless communication systems demand exceptional signal clarity and interference rejection, making the selection of appropriate filtering components critical for optimal performance. A microwave dielectric ceramic filter represents one of the most sophisticated solutions available for high-frequency applications, offering superior selectivity and low insertion loss characteristics that traditional metallic filters cannot match. These advanced ceramic components have revolutionized the telecommunications industry by providing compact, lightweight alternatives that maintain exceptional electrical performance across demanding operating conditions. The unique material properties of dielectric ceramics enable precise frequency control while minimizing unwanted signal distortion, making them indispensable for applications ranging from cellular base stations to satellite communication systems.

Understanding Dielectric Ceramic Filter Technology

Material Composition and Properties

Dielectric ceramic filters utilize specialized ceramic materials with carefully engineered permittivity and loss tangent characteristics to achieve precise frequency response control. These materials typically consist of complex oxide compounds such as barium titanate, calcium titanate, or proprietary formulations that exhibit stable dielectric properties across wide temperature ranges. The ceramic composition directly influences the filter's resonant frequency, quality factor, and temperature stability, making material selection crucial for specific application requirements. Advanced manufacturing techniques enable precise control over ceramic microstructure, resulting in consistent electrical properties and predictable performance characteristics that engineers can rely upon for critical system designs.

The high dielectric constant of these ceramic materials allows for significant size reduction compared to air-filled cavity filters while maintaining equivalent electrical performance. This miniaturization advantage becomes particularly important in modern communication systems where space constraints and weight limitations drive design decisions. Additionally, the inherent stability of ceramic materials provides excellent long-term reliability and consistent performance over extended operational periods, reducing maintenance requirements and system downtime.

Resonator Design Principles

The fundamental operation of a microwave dielectric ceramic filter relies on carefully designed resonator geometries that establish specific electromagnetic field patterns within the ceramic structure. These resonators can be configured as cylindrical, rectangular, or custom-shaped elements depending on the desired frequency response and physical constraints. The resonator dimensions are precisely calculated to achieve the target center frequency while maintaining optimal coupling between adjacent resonators for proper filter response shaping.

Coupling mechanisms between resonators determine the filter's bandwidth and selectivity characteristics, with options including magnetic coupling, electric coupling, or mixed coupling configurations. Engineers must carefully balance coupling strength to achieve the desired passband characteristics while minimizing unwanted spurious responses that could degrade system performance. The Q-factor of individual resonators significantly impacts overall filter performance, with higher Q-values providing sharper selectivity but potentially reducing manufacturing tolerance.

Applications in Modern Communication Systems

Cellular Infrastructure Requirements

Cellular base stations represent one of the largest markets for microwave dielectric ceramic filter solutions, where stringent performance requirements demand exceptional selectivity and low insertion loss characteristics. These systems must handle multiple frequency bands simultaneously while maintaining isolation between transmit and receive paths, making filter performance critical for overall system functionality. The compact size and excellent electrical performance of ceramic filters enable efficient multi-band antenna systems that support current 4G networks while providing upgrade paths for 5G implementations.

Modern cellular systems operate across increasingly crowded spectrum allocations, requiring filters with steep skirt selectivity to minimize interference between adjacent channels. Dielectric ceramic filters excel in these applications by providing sharp transition band characteristics that protect sensitive receiver circuits from out-of-band interference while maintaining low insertion loss in the desired passband. The thermal stability of ceramic materials ensures consistent performance across the wide temperature ranges encountered in outdoor base station installations.

Satellite Communication Systems

Satellite communication applications present unique challenges that make dielectric ceramic filters particularly attractive solutions for both ground-based and space-borne equipment. The weight and size constraints of satellite payloads demand compact, lightweight filtering solutions that maintain exceptional electrical performance throughout the mission lifetime. Ceramic filters provide superior power handling capabilities compared to alternative technologies, enabling their use in high-power transmitter applications without performance degradation.

The radiation-resistant properties of ceramic materials make them suitable for space applications where electronic components must withstand harsh environmental conditions including temperature cycling, vibration, and ionizing radiation exposure. Ground-based satellite communication terminals also benefit from the exceptional frequency stability of ceramic filters, which maintain precise frequency response characteristics despite ambient temperature variations and aging effects that could impact system performance over time.

Performance Characteristics and Advantages

Electrical Performance Metrics

The electrical performance of a microwave dielectric ceramic filter encompasses several critical parameters that determine its suitability for specific applications. Insertion loss represents the signal attenuation within the passband and directly impacts system sensitivity and power efficiency. High-quality ceramic filters typically achieve insertion losses below 1 dB across their operational bandwidth, significantly outperforming many alternative filtering technologies. Return loss characteristics indicate how well the filter impedance matches the system impedance, with values typically exceeding 15 dB across the passband to minimize signal reflections.

Selectivity performance, measured as the transition from passband to stopband, determines the filter's ability to reject unwanted signals while preserving desired communications. Advanced ceramic filter designs achieve stopband rejection levels exceeding 60 dB with transition bandwidths as narrow as 1% of the center frequency. Temperature coefficient specifications ensure stable frequency response across operational temperature ranges, with typical values below 10 ppm per degree Celsius for premium ceramic formulations.

Mechanical and Environmental Benefits

The mechanical properties of dielectric ceramic materials provide significant advantages over traditional metallic filter construction, particularly in applications subject to vibration, shock, or thermal cycling. Ceramic materials exhibit excellent dimensional stability and low thermal expansion coefficients, maintaining precise resonator geometries across wide temperature ranges. This stability translates directly into consistent electrical performance and reduced need for temperature compensation circuits that add complexity and cost to system designs.

Environmental resistance represents another key advantage of ceramic filter technology, with properly sealed units providing excellent protection against moisture, corrosive atmospheres, and contamination. The inherent chemical inertness of ceramic materials prevents degradation from environmental exposure, ensuring long-term reliability in challenging installation environments. Additionally, the high power handling capability of ceramic filters allows their use in high-power applications without the thermal management challenges associated with metallic cavity filters.

Design Considerations and Selection Criteria

Frequency Response Requirements

Selecting the appropriate microwave dielectric ceramic filter requires careful analysis of system frequency response requirements, including center frequency, bandwidth, selectivity, and spurious response specifications. The relationship between filter order and selectivity characteristics must be balanced against size, cost, and insertion loss constraints to achieve optimal system performance. Higher-order filters provide steeper selectivity but increase complexity and potentially reduce manufacturing yield, making the selection of appropriate filter order crucial for cost-effective implementations.

Spurious response suppression becomes particularly important in multi-band systems where harmonic or intermodulation products could interfere with adjacent frequency allocations. Advanced ceramic filter designs incorporate specialized resonator configurations and coupling schemes to minimize spurious responses while maintaining excellent in-band performance. The wide spurious-free frequency range of well-designed ceramic filters often eliminates the need for additional filtering stages, simplifying overall system architecture.

Physical Integration Challenges

Physical integration of ceramic filters into communication systems requires consideration of mounting methods, thermal management, and electromagnetic compatibility factors that influence overall system performance. The ceramic construction requires appropriate mounting techniques that accommodate thermal expansion differences between the filter and its housing while maintaining consistent electrical performance. Proper grounding and shielding arrangements prevent unwanted coupling between the filter and adjacent circuits that could degrade selectivity or introduce spurious responses.

Connector selection and placement significantly impact filter performance, particularly at higher frequencies where connector discontinuities can introduce unwanted reflections and insertion loss. High-quality connectors with appropriate impedance characteristics and low VSWR specifications are essential for maintaining filter performance specifications. Additionally, consideration of manufacturing tolerances and assembly procedures ensures consistent performance across production quantities while maintaining cost-effective manufacturing processes.

Manufacturing and Quality Control

Production Process Overview

The manufacturing of high-performance microwave dielectric ceramic filters involves sophisticated processes that require precise control over material composition, forming techniques, and firing parameters. Raw ceramic powders are carefully formulated to achieve target dielectric properties, then shaped using techniques such as pressing, extrusion, or casting depending on the desired resonator geometry. The forming process must maintain tight dimensional tolerances to ensure consistent electrical performance across production batches.

Firing parameters including temperature profiles, atmosphere control, and cooling rates significantly influence the final ceramic microstructure and electrical properties. Advanced manufacturing facilities utilize computer-controlled kilns with precise temperature and atmosphere monitoring to ensure reproducible ceramic properties. Post-firing processing may include diamond grinding or lapping operations to achieve final dimensional specifications and surface finish requirements that impact electrical performance.

Testing and Validation Procedures

Comprehensive testing protocols ensure that each microwave dielectric ceramic filter meets specified electrical and mechanical performance requirements before shipment to customers. Automated test equipment performs high-speed measurements of insertion loss, return loss, and selectivity characteristics across the specified frequency range and temperature conditions. Statistical process control techniques monitor production consistency and identify potential quality issues before they impact customer applications.

Environmental testing protocols validate filter performance under conditions that simulate actual application environments, including temperature cycling, humidity exposure, vibration, and shock testing. These validation procedures ensure long-term reliability and consistent performance throughout the filter's operational lifetime. Advanced testing facilities may also perform accelerated aging tests to predict long-term stability and identify potential failure modes that could affect field reliability.

FAQ

What frequency ranges are supported by dielectric ceramic filters

Microwave dielectric ceramic filters typically operate across frequency ranges from approximately 500 MHz to 40 GHz, with specific designs optimized for particular frequency bands. Lower frequency applications may utilize larger ceramic resonators to achieve the required electrical performance, while higher frequency designs benefit from the compact size advantages of ceramic materials. The frequency range capability depends on the specific ceramic material properties and resonator geometry, with custom designs possible for specialized applications outside standard frequency ranges.

How do ceramic filters compare to cavity filters in terms of performance

Dielectric ceramic filters generally provide superior size and weight advantages compared to traditional metallic cavity filters while maintaining comparable or superior electrical performance. Ceramic filters typically achieve lower insertion loss and higher Q-factors than equivalently sized cavity filters, particularly at higher frequencies. However, cavity filters may offer advantages in very high power applications or where extremely wide spurious-free frequency ranges are required. The choice between technologies depends on specific application requirements including size constraints, power levels, and performance specifications.

What environmental conditions can ceramic filters withstand

High-quality microwave dielectric ceramic filters are designed to operate reliably across temperature ranges from -40°C to +85°C or higher, depending on the specific ceramic formulation and package design. Properly sealed ceramic filters provide excellent resistance to humidity, salt spray, and other environmental contaminants that could degrade performance over time. Vibration and shock resistance typically exceed military specifications for electronic components, making ceramic filters suitable for demanding applications including mobile communications, aerospace, and industrial environments.

How are ceramic filters customized for specific applications

Customization of microwave dielectric ceramic filters involves optimization of resonator geometry, coupling configurations, and ceramic material properties to meet specific electrical performance requirements. Engineers work closely with customers to define center frequency, bandwidth, selectivity, and spurious response specifications, then develop custom resonator designs and manufacturing processes to achieve these targets. Custom packaging options, connector types, and mounting configurations can be developed to facilitate integration into specific system architectures while maintaining optimal electrical performance and environmental protection.