Electronic circuit designers continuously seek advanced filtering solutions to meet the demanding requirements of modern applications. The evolution of signal processing technology has made high-pass filters essential components in countless electronic systems. An lc high-pass filter represents a critical building block that enables engineers to eliminate unwanted low-frequency components while preserving essential high-frequency signals. These sophisticated circuits combine inductors and capacitors to create precise frequency response characteristics that meet stringent performance specifications.

Understanding LC High-Pass Filter Technology

Fundamental Operating Principles

The operation of an lc high-pass filter relies on the complementary impedance characteristics of inductors and capacitors across different frequency ranges. At low frequencies, the inductor presents minimal impedance while the capacitor exhibits high impedance, effectively blocking signal transmission. As frequency increases, this relationship reverses, allowing high-frequency signals to pass through with minimal attenuation. This frequency-dependent behavior creates the distinctive high-pass filtering characteristic that engineers leverage in numerous applications.

Modern lc high-pass filter designs incorporate advanced materials and manufacturing techniques to achieve superior performance metrics. The integration of high-Q inductors with precision capacitors enables exceptional selectivity and minimal insertion loss. These improvements directly translate to enhanced system performance in applications ranging from telecommunications infrastructure to precision measurement equipment.

Design Considerations and Implementation

Successful implementation of an lc high-pass filter requires careful consideration of multiple design parameters including impedance matching, component tolerances, and thermal stability. Engineers must balance performance requirements against practical constraints such as size limitations and cost considerations. The selection of appropriate inductor and capacitor values determines the cutoff frequency and rolloff characteristics that define the filter's overall performance.

Temperature coefficient matching between reactive components ensures stable operation across varying environmental conditions. Advanced simulation tools enable designers to optimize component values and predict real-world performance before committing to physical prototypes. This approach significantly reduces development time while improving final product reliability.

Leading IC Solutions for 2025

Analog Devices ADF4002 Series

The Analog Devices ADF4002 series represents cutting-edge technology in integrated lc high-pass filter solutions. These devices combine exceptional performance specifications with robust manufacturing quality to deliver consistent results across demanding applications. The series features programmable cutoff frequencies ranging from 1 MHz to 500 MHz, enabling versatility across multiple design requirements.

Advanced process technology enables the ADF4002 series to achieve industry-leading insertion loss characteristics while maintaining excellent stopband rejection. The integrated design approach eliminates the need for external matching networks in many applications, simplifying circuit implementation and reducing overall system complexity. These devices excel in high-frequency communication systems where signal integrity is paramount.

Texas Instruments LMH6702 Platform

Texas Instruments has developed the LMH6702 platform specifically for high-performance lc high-pass filter applications requiring exceptional linearity and low distortion. This innovative solution integrates advanced semiconductor technology with optimized circuit topologies to deliver superior performance metrics. The platform supports cutoff frequencies up to 1 GHz while maintaining excellent phase linearity across the passband.

The LMH6702 incorporates proprietary compensation techniques that minimize group delay variation and ensure consistent amplitude response. These characteristics make it ideal for applications requiring precise signal conditioning, such as radar systems and high-speed data acquisition equipment. The device operates from a single 3.3V supply while delivering exceptional dynamic range performance.

Performance Optimization Strategies

Component Selection Guidelines

Optimal performance from an lc high-pass filter depends critically on appropriate component selection and circuit implementation techniques. High-Q inductors with minimal parasitic capacitance ensure clean frequency response characteristics without unwanted resonances. Similarly, precision capacitors with low equivalent series resistance contribute to minimal insertion loss and excellent temperature stability.

Circuit board layout considerations play a crucial role in achieving theoretical performance levels. Proper ground plane implementation and controlled impedance traces minimize parasitic effects that could degrade filter performance. Component placement strategies that minimize coupling between input and output paths ensure optimal isolation and prevent unwanted feedback effects.

Measurement and Verification Techniques

Comprehensive testing protocols ensure that lc high-pass filter implementations meet design specifications across all operating conditions. Network analyzer measurements provide detailed frequency response data including insertion loss, return loss, and group delay characteristics. These measurements enable engineers to verify theoretical predictions and identify potential optimization opportunities.

Time domain analysis techniques complement frequency domain measurements by revealing transient behavior and settling characteristics. This comprehensive approach to performance verification ensures reliable operation in real-world applications where signal conditions may vary significantly from ideal test scenarios.

Application-Specific Implementations

Telecommunications Infrastructure

Modern telecommunications systems rely heavily on sophisticated lc high-pass filter designs to ensure signal quality and system reliability. Base station equipment incorporates these filters to eliminate spurious low-frequency content while preserving critical communication signals. The demanding requirements of 5G networks have driven significant advances in filter technology, particularly in terms of linearity and power handling capability.

Fiber optic communication systems utilize specialized lc high-pass filter configurations to optimize optical-to-electrical signal conversion. These applications demand exceptional phase linearity and minimal group delay variation to preserve high-speed data integrity. Advanced filter designs incorporate temperature compensation techniques to maintain consistent performance across varying environmental conditions.

Industrial Measurement Systems

Precision measurement applications require lc high-pass filter solutions that deliver exceptional accuracy and stability over extended operating periods. Industrial process monitoring equipment incorporates these filters to eliminate low-frequency noise while preserving critical measurement signals. The harsh operating environments typical of industrial applications demand robust filter designs with excellent temperature and vibration resistance.

Automated test equipment relies on high-performance lc high-pass filter implementations to ensure measurement accuracy across wide frequency ranges. These systems must maintain calibrated performance over thousands of measurement cycles while operating in controlled laboratory environments. Advanced filter designs incorporate self-calibration features to compensate for component aging and environmental variations.

Future Technology Trends

Emerging Materials and Processes

The evolution of semiconductor manufacturing technology continues to enable improved lc high-pass filter performance characteristics. Advanced materials with superior temperature coefficients and lower loss tangents promise enhanced stability and efficiency. Nanotechnology applications in component manufacturing enable smaller form factors while maintaining or improving electrical performance.

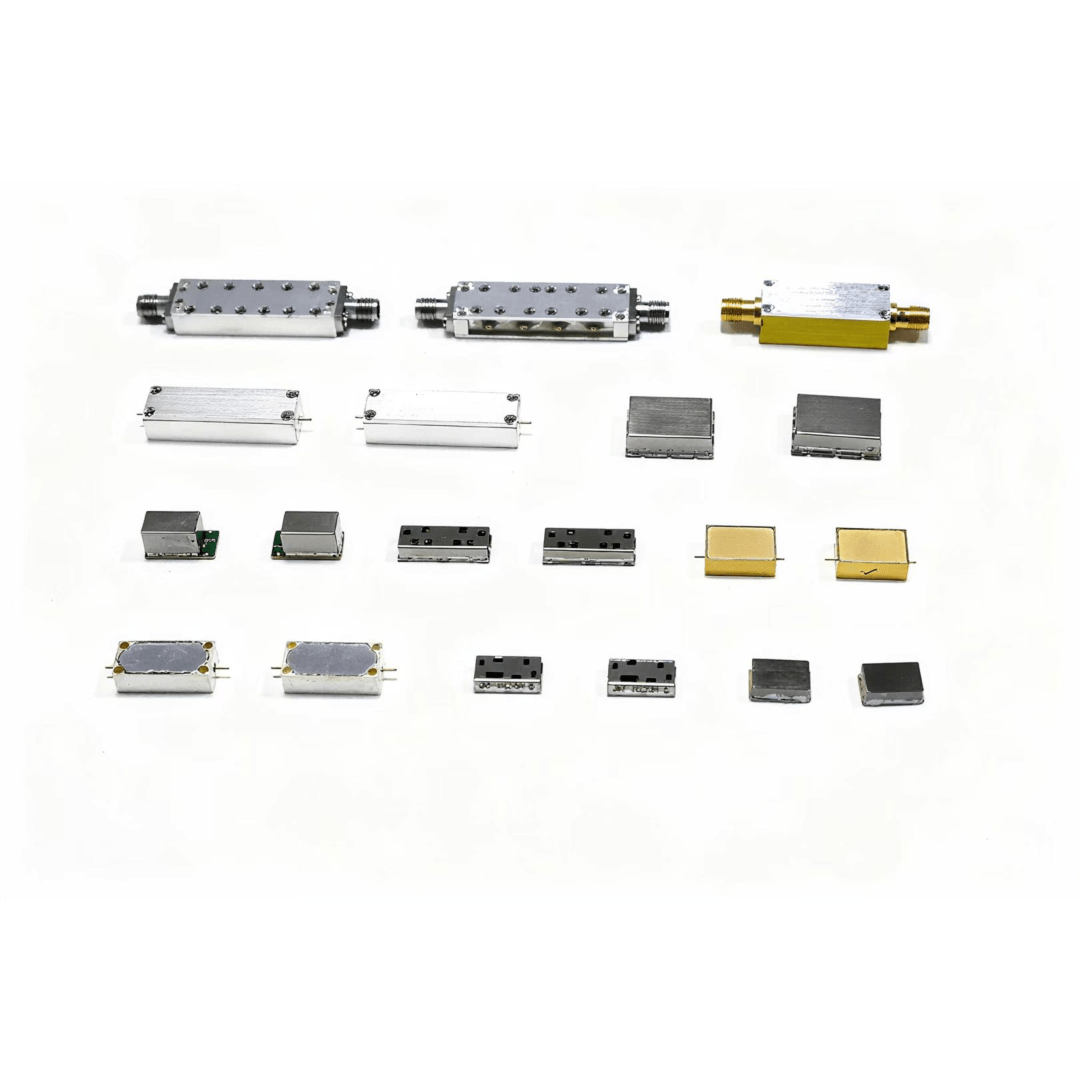

Three-dimensional integration techniques allow complex filter topologies to be implemented in compact packages. These approaches enable higher-order filtering functions while reducing parasitic effects associated with conventional interconnection methods. The resulting improvements in performance density make these solutions attractive for space-constrained applications.

Integration with Digital Signal Processing

Hybrid analog-digital filter architectures combine the advantages of lc high-pass filter technology with the flexibility of digital signal processing. These systems enable adaptive filtering characteristics that can be optimized in real-time based on operating conditions. The integration approach provides superior performance while maintaining the ability to accommodate changing system requirements.

Machine learning algorithms increasingly influence filter design optimization and real-time adaptation strategies. These techniques enable automatic parameter adjustment to compensate for component variations and environmental changes. The result is improved system robustness and reduced maintenance requirements across diverse applications.

Design Implementation Best Practices

Simulation and Modeling Approaches

Advanced simulation tools enable accurate prediction of lc high-pass filter performance before physical implementation. Electromagnetic field solvers provide detailed analysis of component interactions and parasitic effects that influence real-world behavior. These capabilities significantly reduce development time and improve first-pass design success rates.

Multi-physics simulation environments enable comprehensive analysis of thermal, mechanical, and electrical interactions within filter circuits. This holistic approach to design verification ensures reliable operation across all specified operating conditions. Statistical analysis techniques help identify design margins and optimize component tolerances for manufacturing efficiency.

Manufacturing and Quality Control

Consistent manufacturing processes ensure reliable lc high-pass filter performance across production quantities. Advanced process control techniques monitor critical parameters throughout manufacturing to maintain quality standards. Statistical process control methods enable early detection of potential quality issues before they impact delivered products.

Comprehensive testing protocols verify electrical performance at multiple stages of the manufacturing process. Automated test equipment enables efficient screening while maintaining thorough performance verification. Traceability systems ensure complete documentation of component sources and manufacturing history for quality assurance purposes.

FAQ

What factors determine the cutoff frequency of an lc high-pass filter

The cutoff frequency of an lc high-pass filter is primarily determined by the values of the inductor and capacitor components used in the circuit. The relationship follows the formula fc = 1/(2π√(LC)), where L represents inductance and C represents capacitance. Additionally, component tolerances, temperature coefficients, and parasitic elements can influence the actual cutoff frequency in practical implementations.

How do temperature variations affect lc high-pass filter performance

Temperature variations can significantly impact lc high-pass filter performance through changes in component values and parasitic parameters. Inductors may experience variations in permeability and resistance, while capacitors exhibit temperature-dependent capacitance changes. Modern designs incorporate temperature compensation techniques and use components with matched temperature coefficients to minimize these effects and maintain stable performance across operating temperature ranges.

What are the main advantages of integrated lc high-pass filter ICs over discrete implementations

Integrated lc high-pass filter ICs offer several key advantages including consistent component matching, reduced parasitic effects, and improved repeatability. The manufacturing process enables precise control of component values and their relationships, resulting in predictable performance characteristics. Additionally, integrated solutions typically require less board space and offer better electromagnetic shielding compared to discrete implementations.

How can designers optimize insertion loss in lc high-pass filter circuits

Optimizing insertion loss in lc high-pass filter circuits requires careful attention to component selection and circuit implementation. Using high-Q inductors with minimal resistance and low-ESR capacitors reduces resistive losses. Proper impedance matching and controlled circuit board layout minimize reflection losses. Additionally, selecting appropriate filter topologies and avoiding unnecessary complexity helps maintain low insertion loss while achieving desired frequency response characteristics.

Table of Contents

- Understanding LC High-Pass Filter Technology

- Leading IC Solutions for 2025

- Performance Optimization Strategies

- Application-Specific Implementations

- Future Technology Trends

- Design Implementation Best Practices

-

FAQ

- What factors determine the cutoff frequency of an lc high-pass filter

- How do temperature variations affect lc high-pass filter performance

- What are the main advantages of integrated lc high-pass filter ICs over discrete implementations

- How can designers optimize insertion loss in lc high-pass filter circuits